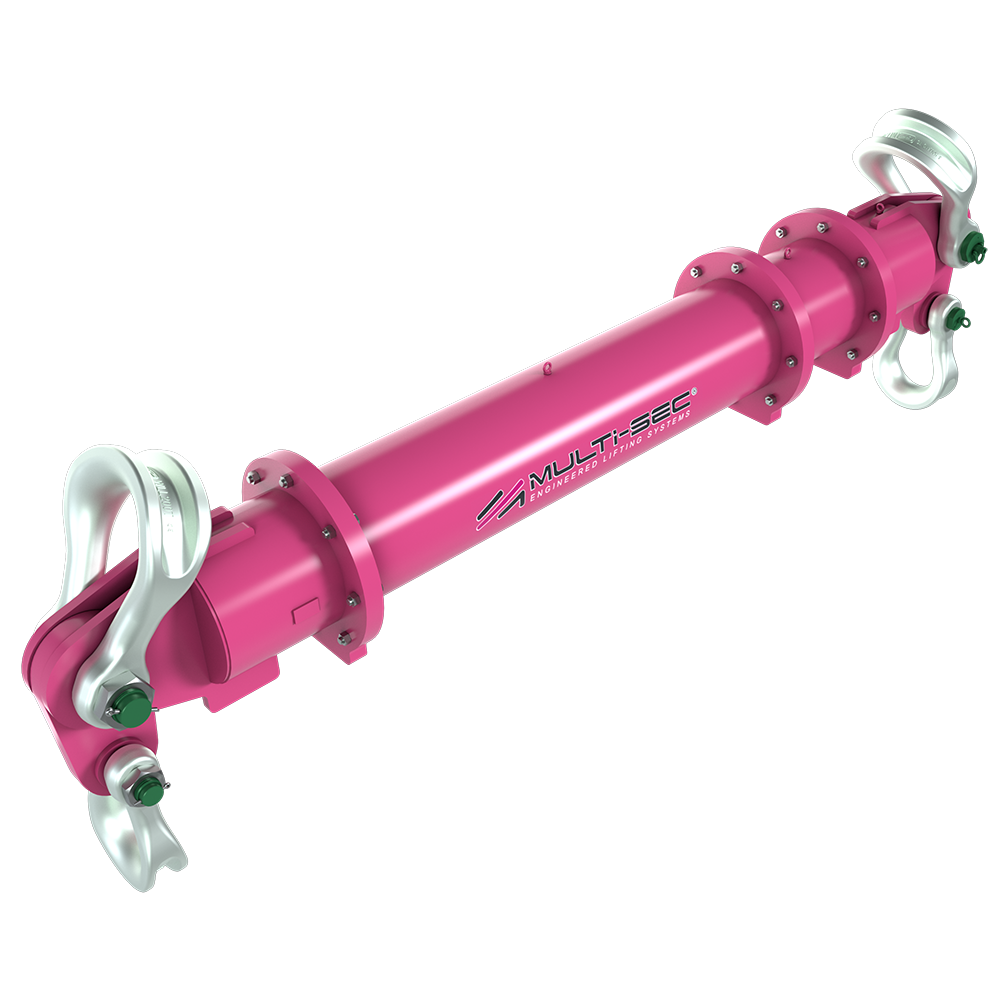

Multisec Modular Spreader Beams are engineered to deliver optimal performance in various lifting applications. Our spreader beams are designed with a modular configuration, featuring two slings attached to shackles at each end. This design allows seamless integration with lifting devices like hoists or cranes, ensuring safe and efficient lifting operations.

Contact our team today to learn how we can provide the perfect lifting solution for your next project.

A modular spreader beam and lifting beam are devices used in material handling and lifting applications. They are typically used in situations where heavy loads need to be lifted, moved, or positioned.

Modular spreader beams and lifting beams are designed to distribute the weight of a load evenly across the beam. They consist of a main beam with two or more attachment points, known as pick points, where the load is attached. The load is then lifted using a crane or other lifting equipment.

Modular spreader beams and lifting beams offer several benefits over traditional lifting methods. They are designed to distribute the weight of a load evenly, reducing the risk of damage or accidents. They can also be customised to fit the specific needs of a particular application and can be easily adjusted to accommodate different load sizes and shapes.

Modular spreader beams and lifting beams are used in a variety of applications, including construction, manufacturing, and shipping. They are commonly used to lift heavy equipment, machinery, and structural components.

When selecting a modular spreader beam or lifting beam, you should consider the weight and size of the load, the number of pick points required, and the maximum load capacity of the beam. You should also consider the material and construction of the beam to ensure it is suitable for your application.

It is important to follow all safety guidelines and regulations when using a modular spreader beam or lifting beam. This includes ensuring that the beam is properly secured and that the load is properly balanced and attached. Regular inspections and maintenance should also be performed to ensure the beam is in good working condition.

At Multisec, we are committed to providing high-quality equipment, exceptional customer service, and competitive pricing. We work closely with our customers to understand their needs and provide solutions that meet their specific requirements.

Additionally, our experienced team of engineers and technicians have the expertise to provide customised solutions and support for even the most complex lifting operations.

Purchasing a modular spreader beam from Multisec is a simple and straightforward process. Browse our selection of modular spreader beams to find the one that meets your lifting requirements.

Once you have identified the beam you need, contact our sales team directly. Our team will work with you to provide a customised quote that includes the cost of the beam and any additional accessories or modifications needed to meet your specific lifting needs.

Our MultiSec Modular Spreader lifting Beam range is not only available for sale, but also for hire from our extensive hire fleet. We understand that not every lifting operation requires a permanent purchase, which is why we offer flexible and cost-effective hire options to suit your specific needs.

Benefits:

Cost effective – Only a small number of components are required to make up a variety of spans and configurations.

Versatile – MultiSec can be configured into virtually any lifting rig to enable the most complicated of structures to be lifted.

Storage – MultiSec can be dismantled and stored in a relatively small area saving valuable space.

Handling – MultiSec are able to be handled more easily than conventional fixed spreader beams.

Transport – MultiSec can be shipped in component form, therefore a smaller, more cost effective vehicle can be used for transportation.

Designed and. manufactured in accordance with:

If you need help or have any questions, please do not hesitate to contact our sales team for guidance.

This product is designed and manufactured in the United Kingdom.